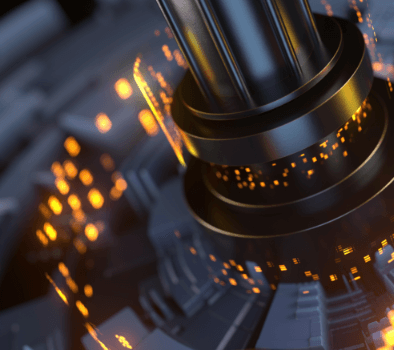

At New Concept Technology, we pride ourselves on being a leader in high-quality, innovative injection technologies and molding services. We specialize in producing high-quality plastic parts with tight tolerances and premium quality, using advanced robotic technology that enhances precision and efficiency. With a deep commitment to innovation, we deliver superior products to cater to the diverse needs of our clients across various industries.

Our facility features cutting-edge machinery, complete with a six-axis robotic arm with laser displacement capabilities. It ensures maximum accuracy with a true position tolerance of ±0.002 inches. This advanced technology improves the quality of our products and streamlines our manufacturing processes, allowing us to meet tight deadlines without compromising on quality.

We can work with numerous materials and help you to choose the best type for your application. Our production team is well-versed in different resin types,, such as Nylon, Ryton, PBT, LCP and many other formulations. With our custom plastic injection molding services, we can provide exactly what your industry requires

Injection molding plays a vital role in ensuring the consistency and accuracy of final products. This specialized manufacturing process is responsible for producing parts and components with utmost precision and exact dimensions. It’s important for:

Partnering with New Concept Technology means more than just gaining access to expert injection molding services. Our customers experience many other advantages, including:

There are several other ways you can mold plastic objects, but injection molding offers manufacturers several significant benefits to manufacturers, such as:

New Concept Technology caters to the varying needs of our clients by providing outstanding precision injection molding services. Some of the industries that benefit greatly from this capability are:

New Concept Technology is your go-to company when you need high-quality injection molding. Our team will work with you to customize your order, ensuring you receive the perfect solution for your project. Reach out to us for a free quotation, and one of our team members will contact you.